CASE STUDY

2020–2023

ABB Robotika Česká republika

ABB is a technology leader in electrical engineering and automation enabling a more sustainable future. By combining technical know-how and software, it delivers solutions to optimise energy production, transport, distribution and building operations. ABB has been an industry leader for over 130 years and with 105,000 employees, ABB brings innovations to the market that accelerate industry transformation.

ABB Robotics and Automation

ABB is the world’s leading robotics and process automation provider. We are the only company with a comprehensive and integrated portfolio that includes robots, autonomous mobile robots and process automation solutions designed and managed by our proprietary software. We help companies of all sizes and industries – from automotive to electronics to logistics – become stronger, more flexible and more efficient. ABB Robotics and Automation supports customers in the transition to the connected and collaborative factories of the future. The division employs approximately 11,000 people at more than 100 locations in 53 countries.

The application was developed for ABB’s Robotics and Automation division, a leading global robotics and process automation provider. It is the only company with a comprehensive and integrated portfolio that includes robots, autonomous mobile robots and process automation solutions designed and managed by our proprietary software. ABB Robotics and Automation supports customers in the transition to the connected and collaborative factories of the future.

Client Brief

We developed the application for the service department of ABB Robotics Czech Republic, which manages thousands of robots in hundreds of companies across the Czech Republic. The goal was to unify communication with the client, simplify it and make it more efficient. Previously, the client used several forms of communication such as e-mail and telephone for monitoring, reporting robot faults or everyday operational communication, which resulted from the preferences of the end customer. Due to the variety of devices end customers use, we agreed to develop the app for web and mobile interfaces for both iOS and Android operating systems.

The world's leading robotics and process automation provider chose eMan

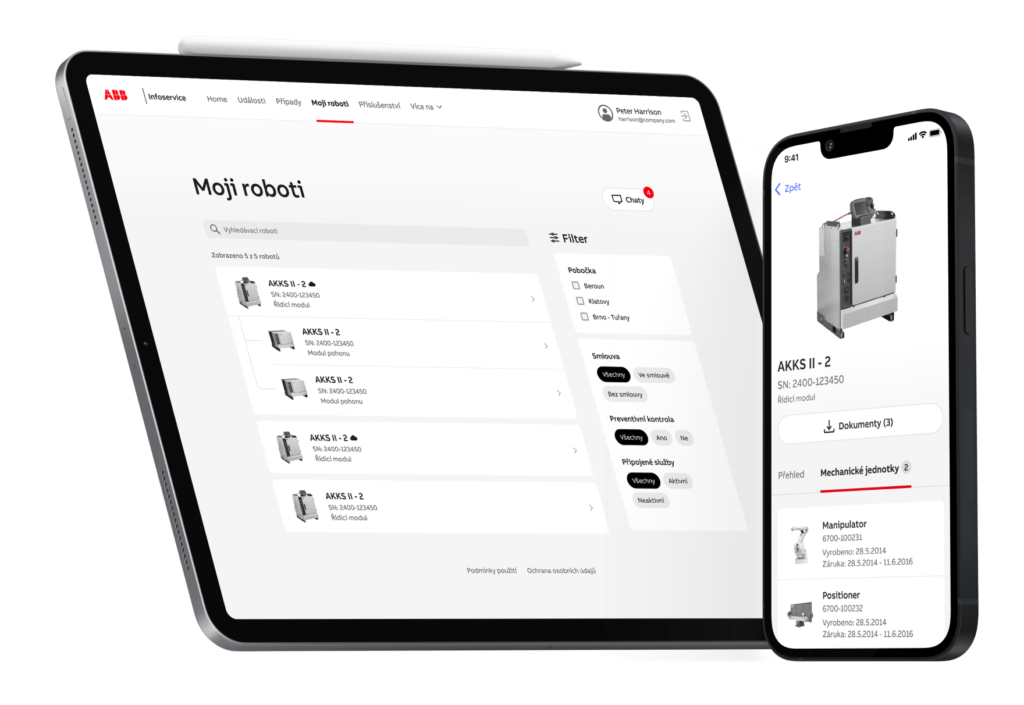

We entered the project in March 2022 and our challenge was to create an app that was easy to understand, intuitive and straightforward. The app had to provide all the information – be it operational statuses, records of service interventions, a list of robots or suitable accessories. Responsiveness had to be kept in mind, considering the variety of devices from PC to mobile to tablet that clients use in their operations.

Thorough preparation was essential

The aim of the app was to make robot control accessible to a wide range of workers.

The most crucial step was taking the know-how, understanding the ecosystem and getting familiar with the back-end on which our application was built. An existing back-end from ABB was used to read data from the database, which was then extended with new application features. To this back-end, we developed the front-end part, which tightened up the processes and logic of each function.

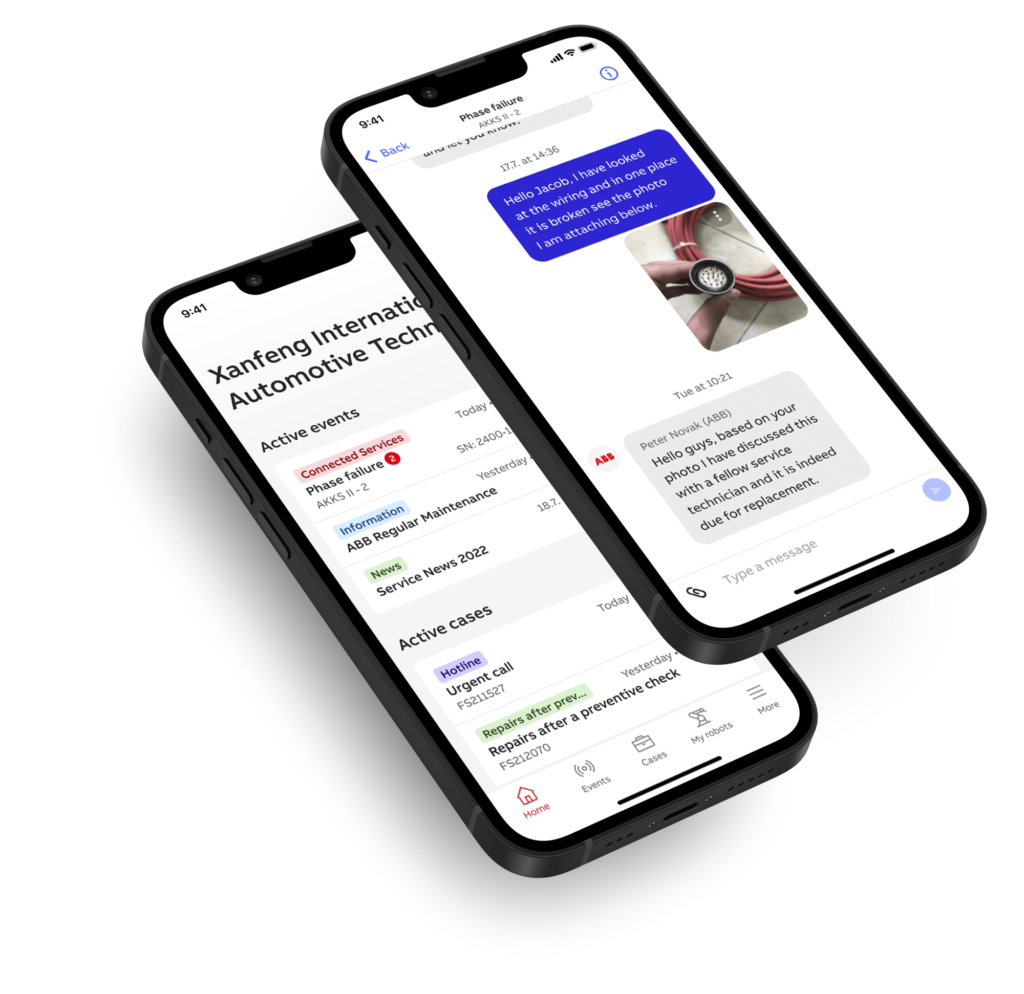

Our development focused on speed of response and minimising downtime. Another challenge was to create a real-time chat between the end client and the engineer, which allowed consulting issues in real-time and through sending documents.

We worked extensively on UX and UI design. The solution went through a Product Discovery process at the beginning of the project to ensure that the outcome would be as beneficial as possible to the end user. The visual aspect of the application also came from our workshop.

Agilní přístup

Projekt byl řízen agilně. Do procesu byl intenzivně zapojen také náš klient, se kterým byl vývoj aplikace průběžně konzultován. Jednotlivé funkce se doplňovaly na základě reálných potřeb koncových zákazníků. Díky vzájemné spolupráci a intenzivní komunikaci zainteresovaných týmů – back-endu (spravovaného třetí stranou) a front-endu – a společným nacházením optimálnějších řešení se dařilo efektivně předcházet prostojům a urychlovat celý proces vývoje.

Agile approach

The project was managed in an agile way. Our client was also heavily involved in the process and was continuously consulted during the app’s development. Individual features were added based on the real needs of the end customers. Thanks to the mutual cooperation and intensive communication between the involved teams – back-end (managed by a third party) and front-end – and jointly finding more optimal solutions, it was possible to prevent downtime and speed up the entire development process effectively.

Agile approach

The project was managed in an agile way. Our client was also heavily involved in the process and was continuously consulted during the app’s development. Individual features were added based on the real needs of the end customers. Thanks to the mutual cooperation and intensive communication between the involved teams – back-end (managed by a third party) and front-end – and jointly finding more optimal solutions, it was possible to prevent downtime and speed up the entire development process effectively.

Improving on the fly

“We have an amazing architecture that allows us to scale the team efficiently. We worked on the project with a team of 10 people whose work was intertwined. Thanks to our technology, there is no interference between the different teams. This gives us high flexibility and efficiency in project management,” explains Lubomír Švorčík, project manager at eMan.

A comprehensive approach to robot control

“The application is well balanced in terms of simplicity/complexity ratio. It simplifies robot inspections for a wide range of workers, monitors all events, notifies the customer of important information from ABB’s digital service via notifications, and also allows the use of chat with a service specialist. We maintain the application across sections so that the programmer can quickly find his way around even in a section he has not worked with before,” explains Leoš Mikulka, Solution Architect at eMan.

In the project’s final phase, we tuned additional requirements that arose from using the application in real life. Further customisation is foreseen.

At the beginning of the project, we focused on the individual process requirements, emphasising the flexibility of the interface and future extensibility for expected changes, both in terms of the use of the whole system and in terms of design. To achieve this, we designed a user interface that not only incorporated existing functionality but also had the potential for further development. The result was an application that met the current needs of the end customers while providing room for improvements that integrated harmoniously into the overall concept.

iOS vs. Android

We knew from the beginning that we wanted to develop mobile applications natively, mainly because of the sustainability and the requirement for speed of the application. We used Kotlin to develop the Android version of the app, Swift for the iOS platform, and the web app was optimized for use on iPads.

WHAT DOES IT DO?

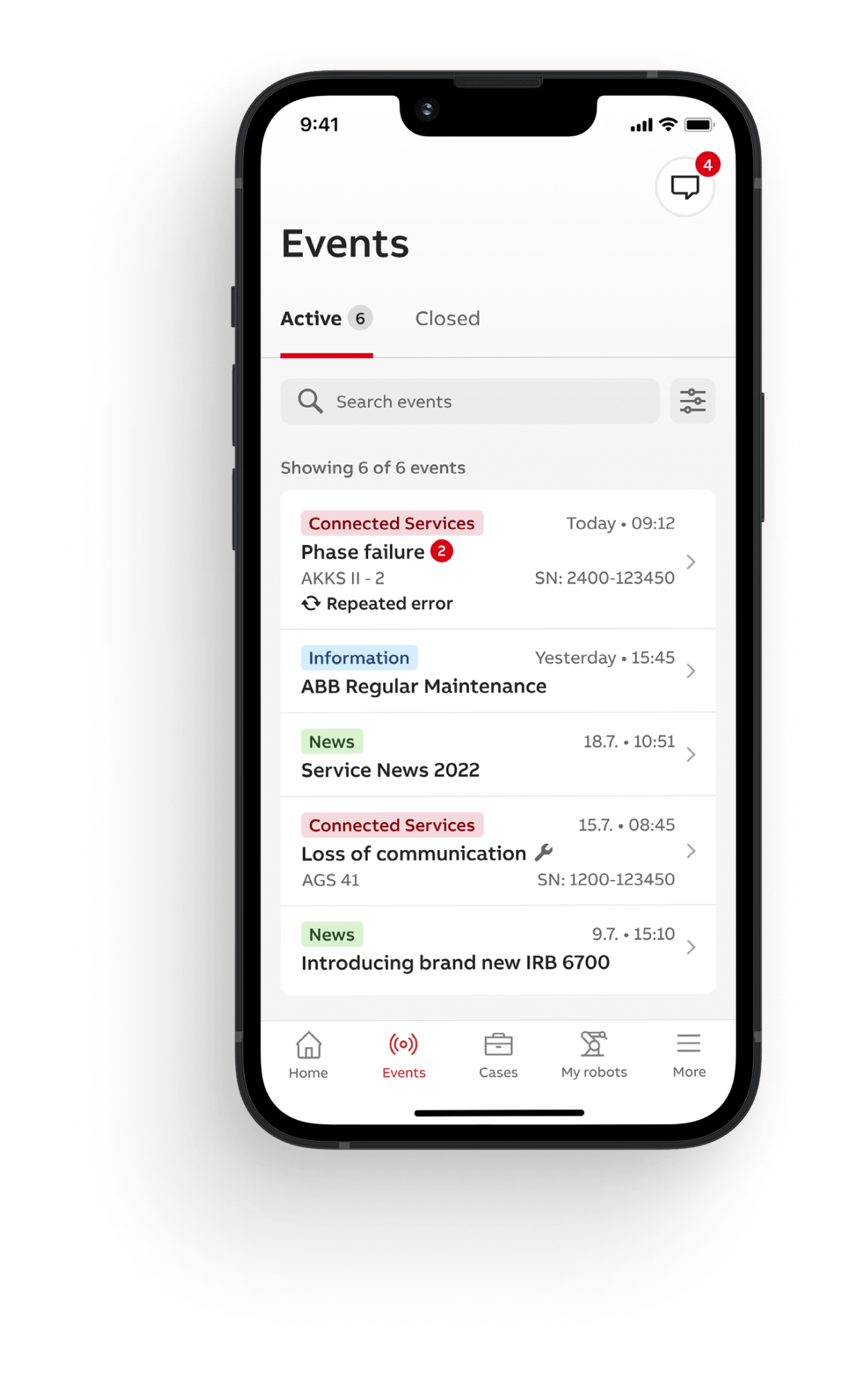

The app presents a perfect overview of everything around their robots. The app monitors all events, and it is thanks to the notifications that the customer will not miss any important information from ABB’s digital service. A chat can be used, through which the user gets help to detect and fix a potential fault. In case of an urgent problem, a hotline with non-stop service support can be confirmed directly in the app. Just as quickly, the user can view an overview of their ABB robots with all the information they need in the Robots section. And if he wants to inquire about new accessories, he simply selects from the menu and sends a non-binding inquiry.

"We are delighted with our cooperation with eMan and happy to have become partners on a full-fledged level. Their contribution goes beyond simply meeting our requirements, as their experts actively develop new ideas and improvements, suggest innovative features and provide valuable feedback towards our goals and objectives. Thanks to the well-functioning interplay between the two parties, we launched our new app in April 2023 and already in the first month 30% of our regular customers started using the app.“

Digital Service Manager, ABB

Robotics & Discrete Automation.

Comprehensive robot service information in one place

The app was an instant hit with users. In the first month of use, 30% of the company’s customers downloaded it. As of October 2023, 68 % of potential users have already used the app. The app streamlines communication, simplifies the operation of robots for customers, and allows them to have a comprehensive overview of their status, as well as quick communication with the service specialist. It is simple, easy to understand and straightforward.

The application is developed for the Czech Republic. The application covers the entire service ecosystem from consultation to ordering spare parts, installation and invoicing. The app is available in two languages. It allows two types of access – customer and admin.

Are you interested in the project we implemented at ABB? Would you like to talk about what we can do for you? Get in touch!

WE HELP COMPANIES

WITH DIGITAL TRANSFORMATION

eMan stocks are being sold on

PX Start at Prague Stock Exchange.

eMan owns following certificates

ISO 9001, ISO 10006, ISO 14001, ISO 20000, ISO 27001 and TISAX.

eMan owns following certificates

ISO 9001, ISO/IEC27001, ISO/IEC 20000-1:2018, ISO14001 and TISAX